- Information Technology

- Data Infrastructure

- Data Tools

- Desktops, Laptops and OS

- Chip Sets

- Collaboration Tools

- Desktop Systems - PCs

- Email Client

- Embedded Systems

- Hardware and Periferals

- Laptops

- Linux - Open Source

- Mac OS

- Memory Components

- Mobile Devices

- Presentation Software

- Processors

- Spreadsheets

- Thin Clients

- Upgrades and Migration

- Windows 7

- Windows Vista

- Windows XP

- Word Processing

- Workstations

- Enterprise Applications

- IT Infrastructure

- IT Management

- Networking and Communications

- Bluetooth

- DSL

- GPS

- GSM

- Industry Standard Protocols

- LAN - WAN

- Management

- Mobile - Wireless Communications

- Network

- Network Administration

- Network Design

- Network Disaster Recovery

- Network Interface Cards

- Network Operating Systems

- PBX

- RFID

- Scalability

- TCP - IP

- Telecom Hardware

- Telecom Regulation

- Telecom Services

- Telephony Architecture

- Unified Communications

- VPNs

- VoIP - IP Telephony

- Voice Mail

- WAP

- Wi-Fi (802.11)

- WiMAX (802.16)

- Wide Area Networks (WAN)

- Wireless Internet

- Wireless LAN

- Security

- Servers and Server OS

- Software and Web Development

- .Net Framework

- ASPs

- Application Development

- Application Servers

- Collaboration

- Component-Based

- Content Management

- E-Commerce - E-Business

- Enterprise Applications

- HTML

- IM

- IP Technologies

- Integration

- Internet

- Intranet

- J2EE

- Java

- Middleware

- Open Source

- Programming Languages

- Quality Assurance

- SAAS

- Service-Oriented Architecture (SOA)

- Software Engineering

- Software and Development

- Web Design

- Web Design and Development

- Web Development and Technology

- XML

- Storage

- Agriculture

- Automotive

- Career

- Construction

- Education

- Engineering

- Broadcast Engineering

- Chemical

- Civil and Environmental

- Control Engineering

- Design Engineering

- Electrical Engineering

- GIS

- General Engineering

- Industrial Engineering

- Manufacturing Engineering

- Materials Science

- Mechanical Engineering

- Medical Devices

- Photonics

- Power Engineering

- Process Engineering

- Test and Measurement

- Finance

- Food and Beverage

- Government

- Healthcare and Medical

- Human Resources

- Information Technology

- Data Infrastructure

- Data Tools

- Desktops, Laptops and OS

- Chip Sets

- Collaboration Tools

- Desktop Systems - PCs

- Email Client

- Embedded Systems

- Hardware and Periferals

- Laptops

- Linux - Open Source

- Mac OS

- Memory Components

- Mobile Devices

- Presentation Software

- Processors

- Spreadsheets

- Thin Clients

- Upgrades and Migration

- Windows 7

- Windows Vista

- Windows XP

- Word Processing

- Workstations

- Enterprise Applications

- IT Infrastructure

- IT Management

- Networking and Communications

- Bluetooth

- DSL

- GPS

- GSM

- Industry Standard Protocols

- LAN - WAN

- Management

- Mobile - Wireless Communications

- Network

- Network Administration

- Network Design

- Network Disaster Recovery

- Network Interface Cards

- Network Operating Systems

- PBX

- RFID

- Scalability

- TCP - IP

- Telecom Hardware

- Telecom Regulation

- Telecom Services

- Telephony Architecture

- Unified Communications

- VPNs

- VoIP - IP Telephony

- Voice Mail

- WAP

- Wi-Fi (802.11)

- WiMAX (802.16)

- Wide Area Networks (WAN)

- Wireless Internet

- Wireless LAN

- Security

- Servers and Server OS

- Software and Web Development

- .Net Framework

- ASPs

- Application Development

- Application Servers

- Collaboration

- Component-Based

- Content Management

- E-Commerce - E-Business

- Enterprise Applications

- HTML

- IM

- IP Technologies

- Integration

- Internet

- Intranet

- J2EE

- Java

- Middleware

- Open Source

- Programming Languages

- Quality Assurance

- SAAS

- Service-Oriented Architecture (SOA)

- Software Engineering

- Software and Development

- Web Design

- Web Design and Development

- Web Development and Technology

- XML

- Storage

- Life Sciences

- Lifestyle

- Management

- Manufacturing

- Marketing

- Meetings and Travel

- Multimedia

- Operations

- Retail

- Sales

- Trade/Professional Services

- Utility and Energy

- View All Topics

Share Your Content with Us

on TradePub.com for readers like you. LEARN MORE

Request Your Free Case Study Now:

"Automotive and Transportation Clean Motion"

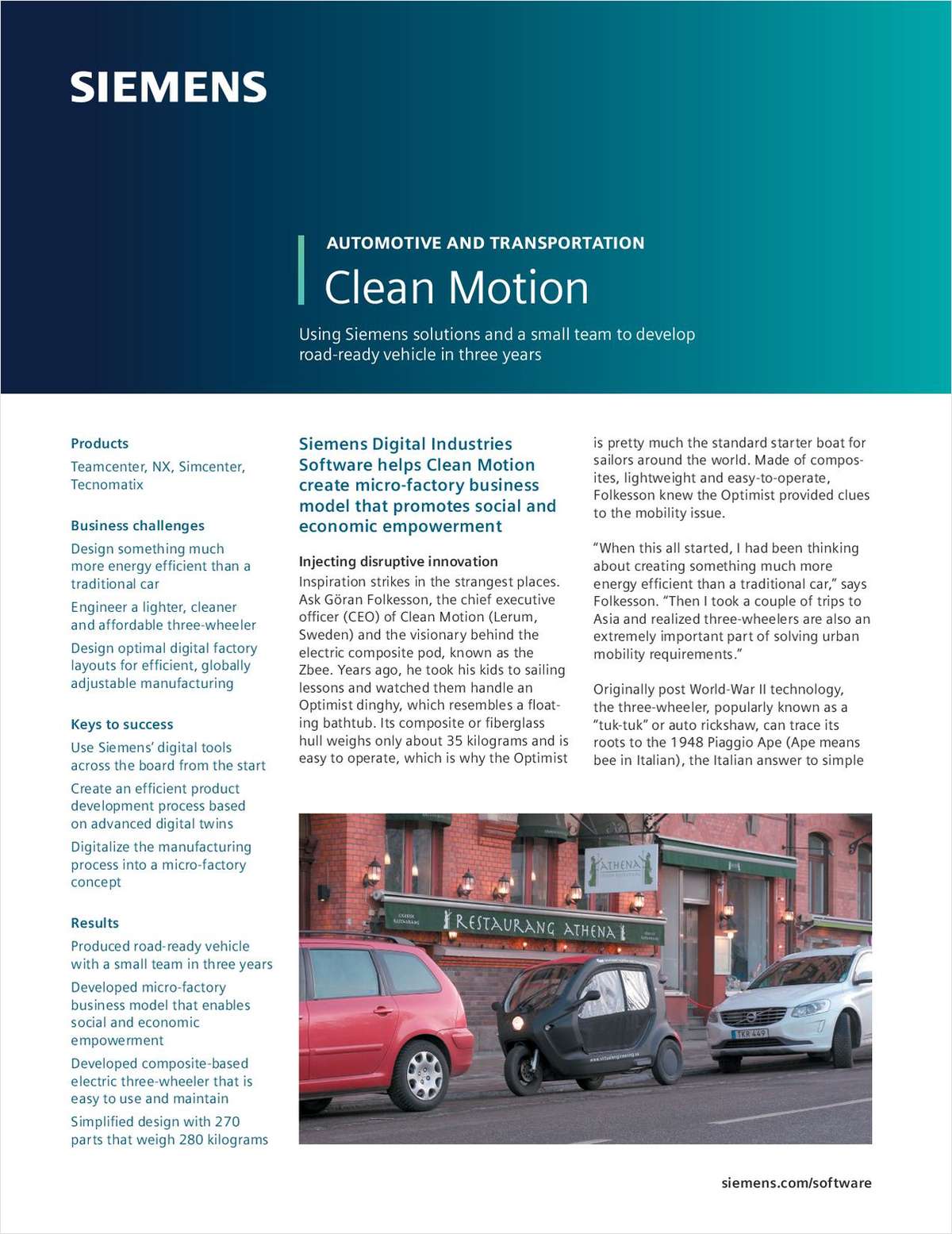

Clean Motion used Siemens digital tools to develop the Zbee, a lightweight electric three-wheeler. The small team created a road-ready vehicle in three years with just 270 parts weighing 280 kilograms. Their micro-factory model enables scalable, sustainable manufacturing globally. Learn how digital twins accelerated development.

Traditional three-wheelers have served urban transport but face challenges from polluting engines and outdated designs. As cities seek cleaner mobility, developing lightweight, affordable electric vehicles poses engineering hurdles.

This case study shows how a small team used digital tools to transform vehicle development. By integrating CAD, simulation, and manufacturing, they created a composite-based electric three-wheeler and a scalable micro-factory. Key achievements include:

· Cutting weight to 280 kg with advanced composites

· Reducing design to 270 parts for easy assembly

· Simulating 100,000 factory layouts to optimize efficiency

Explore how digital transformation drove innovation.

Offered Free by: Siemens

See All Resources from: Siemens

Thank you

This download should complete shortly. If the resource doesn't automatically download, please, click here.